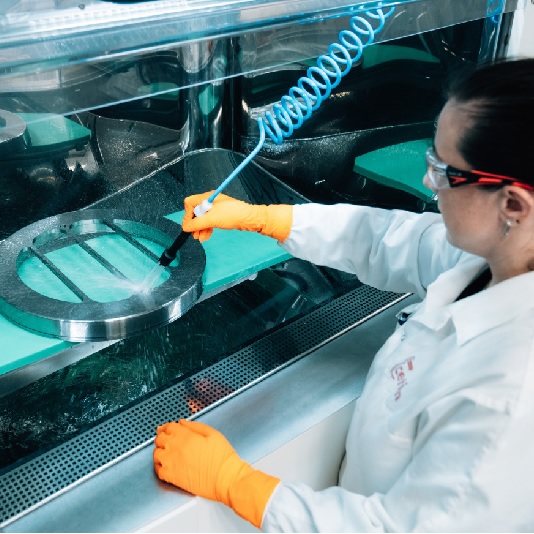

Cetim has just acquired a brand-new cleanliness analysis bench, the only one of its kind in France, designed for large parts. This investment is part of Cetim’s active approach in this field.

Measurements of particulate cleanliness on parts up to one meter long and weighing 100kg.

This is what is offered by the new test bench dedicated to the cleanliness of parts that has been installed in Cetim’s laboratory. Operational since beginning of this year, this bench has been the first in France to enable a laboratory to process parts with these characteristics.

Comprehensive support

Aware that the particulate cleanliness of parts constitutes a real competitive advantage for a large number of manufacturers, Cetim has in recent years initiated an approach to support product and component manufacturers in particular analysis.

Indeed, whether they work in the mobility, energy, health, space or defence sectors, they must guarantee a level of cleanliness of parts capable of meeting the increasingly demanding standards in force.

To help them better understand their customers’ issues, measure the cleanliness level of their parts, control the cleanliness level of their production site, and develop the appropriate cleaning skills and processes, Cetim offers them tailor-made support. Audits, advice, setting up an optimal organization at a controlled cost, determining good practices and means of Measurements and cleaning, training…, its experts engineers follow them throughout their project to enable them to control the quality and reliability of their products and secure their investments. Cetim also provides manufacturers with access to a range of testing facilities so that they can analyze all types of parts, from micromechanical components to tubes, including large components with a high mass.

This approach is in line with an essential complement to two major strategic projects led by Cetim to meet the new challenges generated by the development of hydrogen and the electrification of transport. The HyMEET project aims to develop know-how and experience in cleanliness control with a view to increasing the reliability of new hydrogen solutions, to reflect on optimal industrial organization and to help develop appropriate technological solutions. In this respect, the bench’s wide analysis capabilities mean that it can address the key issues of cleanliness of hydrogen system components and the development of standards. It does the same for batteries, providing real added value for the E-Mobility project, which is looking at the mechanical challenges to be met as part of the growing electrification of transport.

Discover our cleanliness Laboratory in video

Join our conference at Hyvolution 2025 on “cleanliness throughout the hydrogen value chain” on Wednesday January 29 from 4:00 to 4:20 pm, Hall4/Forum 2.